Since any internal combustion engine requires three things to run - fuel, oxygen and ignition, the intake system of your car does an incredibly important job by providing the motor with air. Your car's designers will have fitted your motor with an intake that strikes a balance between power, efficiency and manufacturing costs and as such, there are a few things that can be done to potentially increase the former two. Before we get into the modifications that can be done to your intake system though, let's first have a look at the various types, and some of the common terminology.

What is Aspiration?

There are a few different methods for providing an engine with its oxygen - the process of which is called aspiration. The most common is a simple air intake duct, fitted with a filter. This lets the motor suck in oxygen that is at atmospheric pressure, and is the simplest and most common form of intake. Vehicles fitted with this type of intake are referred to as naturally aspirated.

The other class is forced induction, which makes use of some type of compressor that first compresses the air before feeding it into the engine, these are commonly referred to as either having forced induction or simply boost. Compressing air increases its density, and allows better combustion as there are more oxygen atoms per quantity of air present in the combustion chamber than there would be at atmospheric pressure. In turn, this allows more fuel to be added for each cycle of the engine - resulting of course, in more power. The two main types of compressor used, are turbochargers and superchargers - we'll go into more detail on each system below. You may have heard people refer to how much boost their car has, either as psi, or as bar both refer to the pressure that the air is compressed to above the standard atmospheric pressure - but are each different measurement units. One Bar is roughly equal to the standard atmospheric pressure at sea level, and is around 14.5 psi (pounds-per-square-inch.)

What is a Naturally Aspirated, or N/A engine?

As mentioned above, most cars are naturally aspirated. They rely on internal compression to maximise the use of their oxygen supply, and so don't have anything that compresses the air prior to feeding it into the combustion chambers. With N/A cars, you needn't worry about as many complex additional parts or ducting, and the only part of the intake that usually requires attention is the air filter. They are generally pretty resilient as there is no added stress on the motor, so N/A cars are often reported to be the cheapest and most reliable option. However, with reliability and cheap manufacturing costs there generally come a few compromises. In this case, the compromise is usually in the maximum power output of natural aspiration, with many that seek more power without boost, having to end up doing a whole lot more work (not to mention, spending a whole lot more money) to get similar power levels as they would with a turbo or supercharger strapped to their motor.

Unfortunately, it is often not feasible to simply bolt on a forced induction system, due to the original motor's compression ratio, tuning, fuel delivery system and most often its position in the engine bay.

What is a Turbocharger?

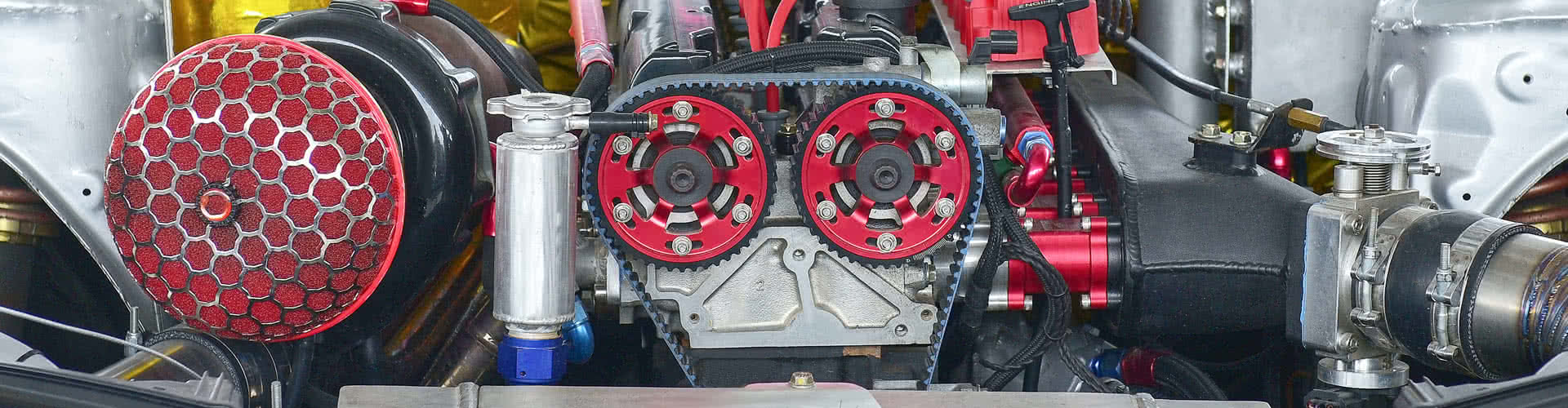

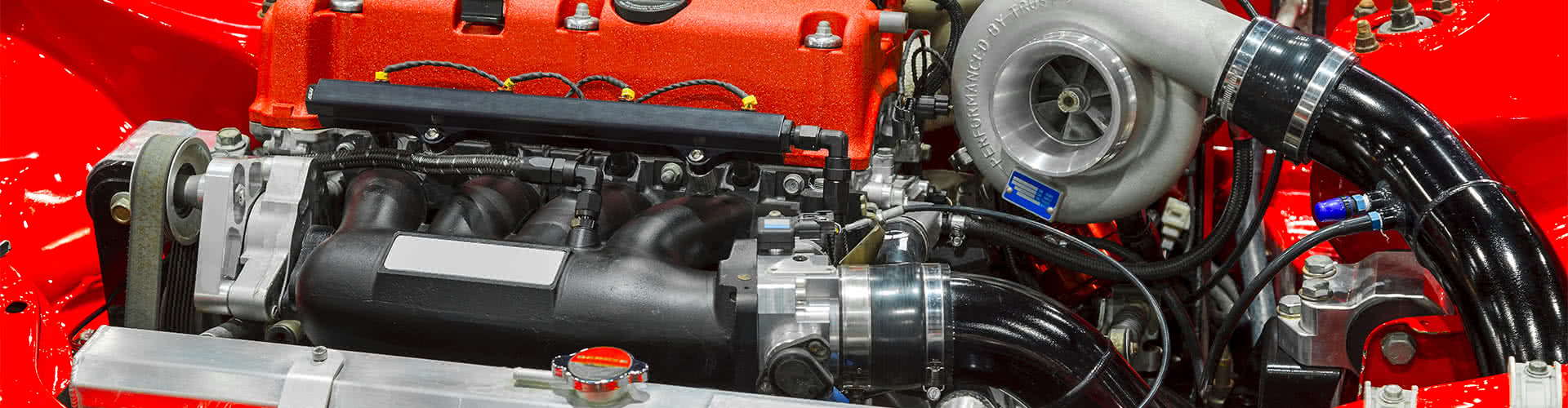

The first type of forced induction system we'll look at is the turbocharger, or turbo for short. These are probably the most commonly encountered and widely known type of forced induction, and are used in a wide variety of vehicles, from most manufacturers, and across both petrol and diesel fuel types. They consist of a turbine and a compressor that are housed in two different chambers. The turbine spins as exhaust gas flows through it, and this in turn spins the compressor that (as you can probably guess) compresses air for the intake.

Turbos used to be considered to be a type of supercharger, however they've since been thought of to as their own category of forced-induction system as the two technologies developed. Where they differ from superchargers is that they are not mechanically driven, but rather powered by the exhaust gases of the motor, meaning that they are capable of increasing both power and efficiency without putting additional mechanical strain on the engine. The simple downside is that their power production will lag behind the revs of the engine, since they require a flow of exhaust gases in order to spool up their turbines, and most engines are incapable of producing enough exhaust flow at idle to spool up the turbine.

There have been many developments made to turbocharger technology since their invention back in the late 1800s, and as a result there are countless combinations of size, style and additional componentry that make dealing with turbos almost a science of its own - from blow-off valves, intercoolers and wastegates, to twin-turbo and twin-scroll turbos, a lot of the jargon can sound like an entirely made-up language.

Twin-turbo: This one's pretty easy, since it's basically two turbos. That said however, the setup can be fairly complex - turbos can either be run in parallel, or in sequence and the second turbo (usually a larger one) may even be switched on at certain rpm. The benefit of these sorts of setups are that the smaller turbo can spool up quicker, resulting in less turbo lag.

Twin-scroll Turbo: A twin-scroll turbo, is a turbocharger that has two separate inlets for exhaust gases that are usually set up to feed from particular cylinders. The reason for this is that in many higher performance motors, there is slight overlap in the valve timing. Twin scroll turbos can scavenge the exhaust gases that are released during overlapped the valve opening times and thus improve efficiency, as well as potentially reduce emissions. Usually these turbos will have one inlet that suits peak performance, and another that provides a quicker spool, and therefore better responsiveness.

What is a Wastegate?

A wastegate is a bit of plumbing that allows excess pressure to be vented to the exhaust - therefore bypassing the turbine and so not causing excess boost. Some wastegates are electronically controlled, but most operate on a spring loaded diaphragm

What is a Blow-off valve?

These function like the wastegate, however are situated on the intake side of the turbo setup, and vent the excess air that's left after the throttle closes. Most blow-off valves are aftermarket, and specifically designed to amplify the sound of the air exiting the intake, and will vent the excess air to the atmosphere. These are illegal in some parts of Australia for a couple of reasons - the most obvious of which is that when there is a lot of high pressure air detected by the sensors in the intake, the amount of fuel is increased to compensate. When this air is then vented and not used, the excess fuel will then be mixed with a lower quantity of air, and so will result in unburnt fuel being emitted from the exhaust as harmful gases. The other main reason is that they are often pretty noisy, and so can annoy or distract other motorists.

What is a Intercooler?

One of the most common additions to a turbocharged engine is that of an intercooler - a device that is designed to cool the air before it is forced into the engine. The reason that these are so valuable is that when air is compressed, it heats up and so loses some of the density that it gained from having been compressed in the first place. This can lead to knocking and premature detonation, which can cause damage to the internal components of the motor.

Variable-geometry/ variable vane turbos: These fancy turbos have little movable vanes that adjust the airflow into them. They can therefore mimic turbos of smaller size at lower rpm, and will in turn reduce lag and improve efficiency. They can be controlled either by vacuum, hydraulics or electronics and are often far more complex than standard turbos.

What is a Supercharger?

If you've seen Mad Max (which is mandatory viewing for all Australians right?) then you'll be familiar with superchargers. They aren't however just giant belt things sticking out of bonnets, but rather come in a variety of forms, with two main categories - Positive displacement, and dynamic. We'll explain these below. Supercharger technology predates turbocharging, and as mentioned above the latter were originally referred to as turbosuperchargers however since the early days, the technology has been gradually improved and the two remain distinct categories. Within the supercharger category however, the basic principle has remained pretty much the same since their introduction - they utilise a mechanical drive to compress air, and force-feed it into the intake.

What is a Positive displacement supercharger?

The most common, and most famous type of superchargers are positive-displacement pumps and can be further divided into internal compression and external compression types. Internal compression superchargers compress the air that is sucked into them, and feed this to the engine directly. They are usually rated with a specific compression ratio, at which there is no backflow from the supercharger to the intake, and they operate at peak performance.

External compression superchargers force air into the engine at ambient pressures, which builds up in the intake and this backflow actually compresses the air as it tries to reach a pressure-equilibrium. THese types of superchargers are generally pretty rubbish when used at high boost levels, due to the inefficiency of the way they compress the incoming air.

What is a Dynamic Compressor?

Superchargers of this type work by accelerating air in a similar fashion to turbochargers. In fact, they fairly well resemble turbos, except that they utilise a mechanical drive to do the job that the exhaust gases do in a turbo. They aren't widely used by automotive manufacturers, but are instead a popular after-market modification where they are often supplied with intercooling and related plumbing and so can be installed with minimal additional fabrication required.

Why is Forced induction better?

Whether considering turbos or superchargers the primary benefit is an increase in power. For turbos there is an added benefit of a boost (no pun intended) to your efficiency too. Superchargers on the other hand are often used with motors that already produce a fair bit of power, since their mechanical drive actually saps power to create power! Therefore an engine needs to be able to withstand the added strain of the mechanical drive, and take the initial performance hit in order to then produce additional gains.

Either way, adding forced induction does require a variety of other modifications be done to an engine - the most important of which is probably a reduction in its compression ratio. Additional to this may be fabrication of brackets and ducting, and in the case of turbos, usually specialised engine management.

When weighing up the options, be sure to work out what sort of power delivery you are after and just how much increasing the power will affect the way your car drives. Also make sure that you budget for any additional plumbing, fabrication, belts, exhaust modifications and related engine work, on top of the initial forced induction system.

What are the intake system components?

The easily accessed parts of your intake will generally consist of a filter, some ducting and some sensors, as well as a throttle body and various vacuum hoses. Depending on the complexity of your setup, and whether you have a forced induction system or not, the parts that you might want to familiarise yourself with, will vary somewhat. Below are a few of these components, and a brief description of what they are and what they do.

- Air filter - Your air filter is responsible for screening out rubbish that may otherwise find its way into your intake and wreak havoc on your motor. Whether this is dust, dirt, twigs, insects or even small animals (or at least bits of them) your filter needs to be up to the task of blocking foreign objects from entering your engine, as well as still allowing good airflow. There are a variety of different filter types, and different ways that these can be mounted, as well as different places that they can be located. Aftermarket filter setups can increase airflow (and therefore power) as well as offering extended durability or the ability to wash and reuse the filter elements.

- Air hoses/ducting - Connecting the various intake components are specially designed ducts that are usually designed to maximise the airflow to the engine, as well as keep manufacturing costs down. Replacing these with aftermarket ducts can go a long way towards increasing your engine's ability to breathe, however be sure to allow for the installation of the various sensors and extra hoses that may be present in your factory setup.

- Airflow meter - The airlfow meter measures the flow of air into the intake, and tells your computer how much fuel to inject, as well as what the timing should look like. It works in conjunction with the other sensors in the motor to do this.

- Manifold pressure sensor - Commonly called a MAP sensor, this sensor measures the pressure in the intake manifold, and sends this info to the computer so that it can calculate the fuel and timing adjustments it needs to run correctly. It essentially does the same job as the airflow meter, and as such most naturally aspirated cars will only have one or the other. Cars with forced induction intakes, will usually have an airflow meter before the supercharger or turbo, and a MAP sensor after it.

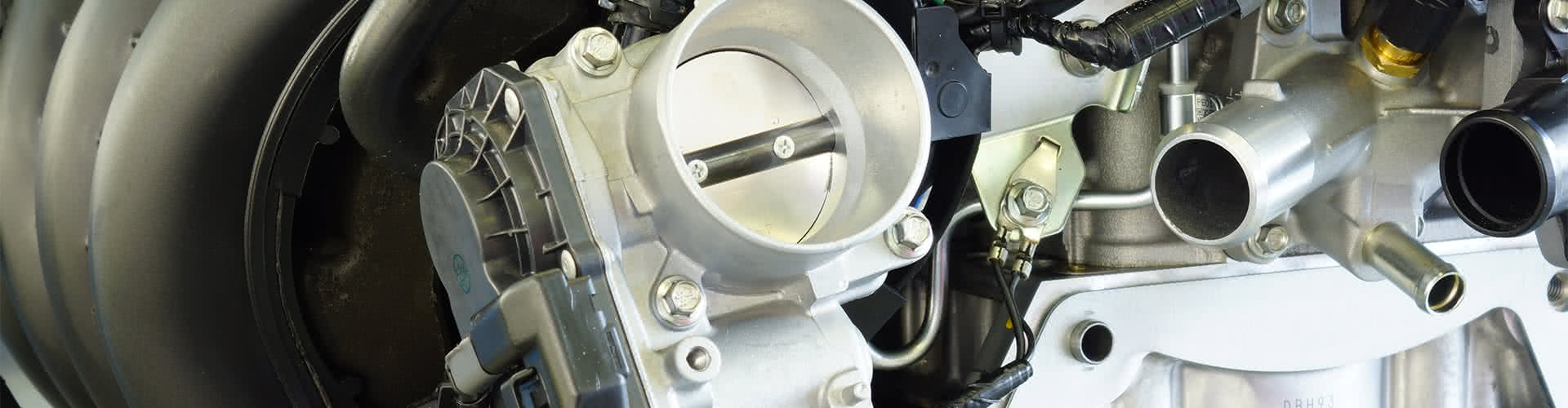

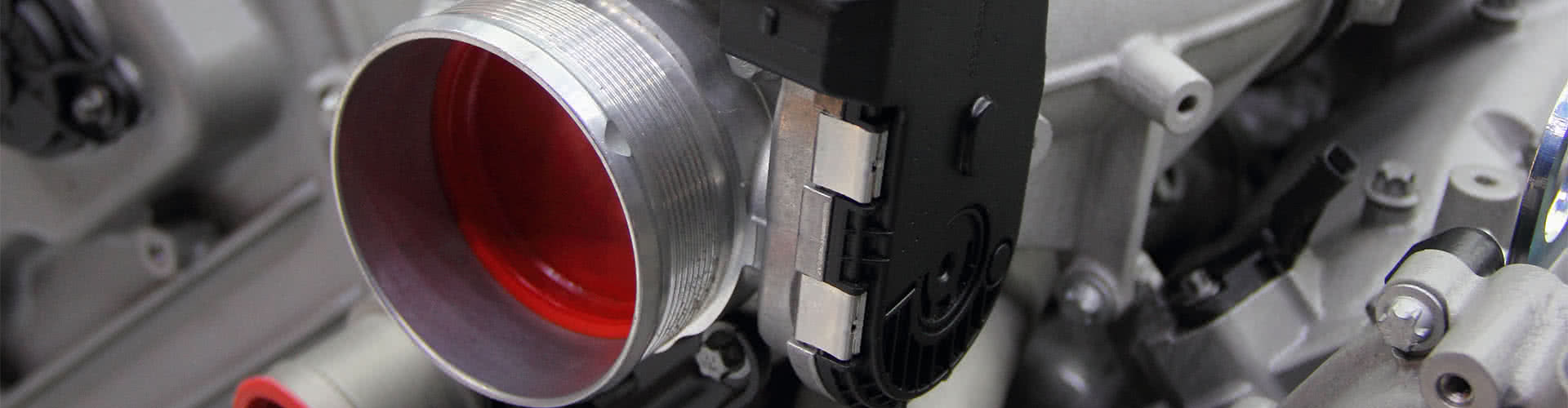

- Throttle body and Drive-by-wire - Fuel-injected vehicles are equipped with a throttle body, which contains a valve that opens to allow air to enter the engine, or closes to stop it. It is usually hooked up to a physical cable that is pulled when you press the accelerator In cars with drive-by-wire technology, this cable is replaced with a sensor on the accelerator pedal that transmits data to an electronically controlled actuator on the throttle. The car's computer converts the pressure and position of the accelerator pedal into a specific movement of the actuator. Fun fact: This system was first introduced back in 1988, for the BMW 7-series as EML!

Tools commonly required when working on intake systems

Most jobs that you might want to carry out on your intake system won't require the use of many specialist tools, and can be carried out pretty easily - even if you want to take apart a supercharger or turbo, or carry out more complex and involved tasks, then the list of tools you'll usually need is still pretty short. Other than the standard socket-set/spanner combo that I'll recommend in all of these sections, you may find that a screwdriver set and a pair of pliers are most useful in disconnecting hose-clamps and other ducting components. Most sensors will usually unplug, though electrical contact cleaner is handy to have, as some of these plugs can be exposed to a bit of dirt, and sensors should always be clean in order for them to work correctly. Be sure to use a drip-tray, gloves and safety glasses if you need to disconnect any component that is attached to a fluid supply (such as coolant or oil feeds on turbos) and make sure you have some shop-rags on hand to clean up any spills. Testing for manifold leaks can be done using a vacuum tester, and often they double as pressure testers for use in fuel system testing. Rebuilding or mounting a turbo or supercharger will often require a variety of sealants or gasket maker, though won't usually require any additional tools unless you really want to get serious, and start fabricating stuff!

*Important information* - Click here to read more about our DIY Advice Terms and Conditions.